DuraLub Thin Coatings PVD – PHYSICAL VAPOUR DEPOSITION Fine coating process (2-5µm thick) vacuum deposition where a material is transformed into steam, finally transported and deposited on the surface of a substrate. ADVANTAGES INCREASED PERFORMANCE LIFE (CUTTING TOOLS, MOLDS, DIES, CUTTING AND SHAPING, ETC..) REDUCED MACHINE DOWNTIME REDUCED MAINTENANCE COSTS […]

Read More

D-Mold Thin Coatings PVD – PHYSICAL VAPOUR DEPOSITION Fine coating process (2-5µm thick) vacuum deposition where a material is transformed into steam, finally transported and deposited on the surface of a substrate. ADVANTAGES: INCREASED PERFORMANCE LIFE (CUTTING TOOLS, MOLDS, DIES, CUTTING AND SHAPING, ETC..) REDUCED MACHINE DOWNTIME REDUCED MAINTENANCE COSTS […]

Read More

CrcMax thick coatings Projeção Térmica Neste processo é estabelecido um arco elétrico que provoca a fusão de dois arames alimentados continuamente. Por meio de um jato de ar de alta pressão o metal fundido é projetado contra o substrato. Com este processo, tipicamente obtém-se revestimentos com porosidade intrínseca na ordem […]

Read More

MasterTiN Thin Coatings PVD – PHYSICAL VAPOUR DEPOSITION Fine coating process (2-5µm thick) vacuum deposition where a material is transformed into steam, finally transported and deposited on the surface of a substrate. Advantages INCREASED PERFORMANCE LIFE (CUTTING TOOLS, MOLDS, DIES, CUTTING AND SHAPING, ETC..) REDUCED MACHINE DOWNTIME REDUCED MAINTENANCE COSTS […]

Read More

Hardinite Thin Coatings PVD – PHYSICAL VAPOUR DEPOSITION Fine coating process (2-5µm thick) vacuum deposition where a material is transformed into steam, finally transported and deposited on the surface of a substrate. ADVANTAGES INCREASED PERFORMANCE LIFE (CUTTING TOOLS, MOLDS, DIES, CUTTING AND SHAPING, ETC..) REDUCED MACHINE DOWNTIME REDUCED MAINTENANCE COSTS […]

Read More

HardCut thin Coatings PVD – PHYSICAL VAPOUR DEPOSITION Fine coating process (2-5µm thick) vacuum deposition where a material is transformed into steam, finally transported and deposited on the surface of a substrate. ADVANTAGES INCREASED PERFORMANCE LIFE (CUTTING TOOLS, MOLDS, DIES, CUTTING AND SHAPING, ETC..) REDUCED MACHINE DOWNTIME REDUCED MAINTENANCE COSTS […]

Read More

HardTribo thin coatings PVD – PHYSICAL VAPOUR DEPOSITION Fine coating process (2-5µm thick) vacuum deposition where a material is transformed into steam, finally transported and deposited on the surface of a substrate. Advantages Increased performance life (Cutting tools, molds, dies, cutting and shaping, etc..) Reduced machine downtime Reduced maintenance costs […]

Read More

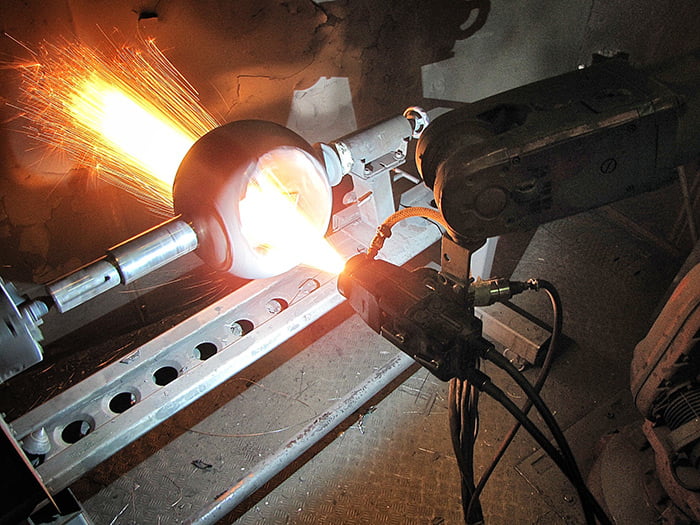

EAWS – Electric Arc Wire Spray thick coatings Thermal Projection: In this process, an electric arc is established which causes the fusion of two wires continuously fed . By means of a jet of high pressure air is projected molten metal onto the substrate . With this process coatings are […]

Read More

HVOF – High Velocity Oxi-Fuel Thick Coatings Thermal Projection The process is based on continuous oxygen combustion of a fuel. Combustion gases entering a chamber , where the raw material in powder form injected axially through the flow stream of an inert gas , usually nitrogen.The high gas pressures associated […]

Read More

Ceramic Materials APS – Atmospheric Plasma Spraying thin coatings Thermal Projection The process basically relies on the introduction of the raw material in particulate form within the plasma jet , in order to accelerate them and fuse. The process is based on the formation of plasmogen means , from the […]

Read More