- +351 239 980 430

- info@duritcoatings.pt

- Mon-Fri: 9:00 - 18:00

- Follow Us

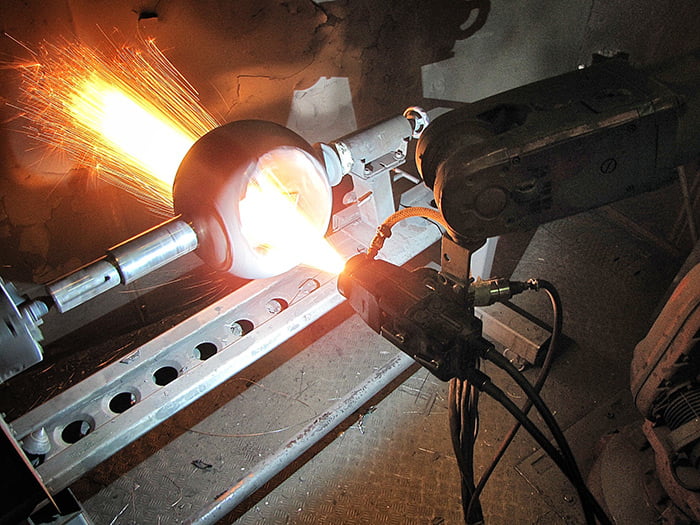

EAWS - Electric Arc Wire Spray

thick coatings

Thermal Projection:

In this process, an electric arc is established which causes the fusion of two wires continuously fed . By means of a jet of high pressure air is projected molten metal onto the substrate .

With this process coatings are usually produced intrinsic porosity of about 3 %, and the levels of adhesion of 40 MPa . The typical thickness of the coatings produced with this technology is between 300 and 2.000μm .

Advantages

Increased longevity of the components

Cost reduction

Reduced downtime / maintenance

Increased overall productivity

Better product quality

Materials and Metal Alloys:

Mo99.9+, Cu5Al, Ni20Cr, AISI420, AISI316, Liga C-276, etc…

- Raw material : wire.

- Typical feedstock flow : 10 to 20 kg / h.

- Typical particle velocity of 100 m / s .

- Power source: electric arc.

- Temperature energy source : 5500 º C

- Typical voltages accession : 15-40 MPa.

- 3% typical porosity .

- Thickness of layers : 200-5000 microns.

Objecives

Adapt and improve surfaces for applications that will be submitted , giving them characteristics:

- Resistance to wear (abrasion , erosion and friction) ;

- Resistance to corrosion and oxidation ;

- Conductivity or electrical insulation, thermal or magnetic ; optics ;

- Biocompatibility

contacts

- Parque Industrial de Taveiro Lote 41 e 42 3045 - 504 Taveiro - Coimbra | Portugal

- Calls to Portuguese landline Network : (+351) 239 980 430

- info@duritcoatings.pt