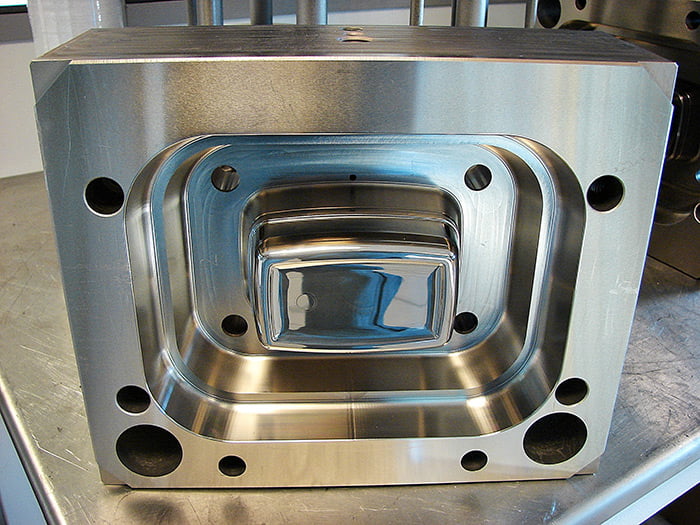

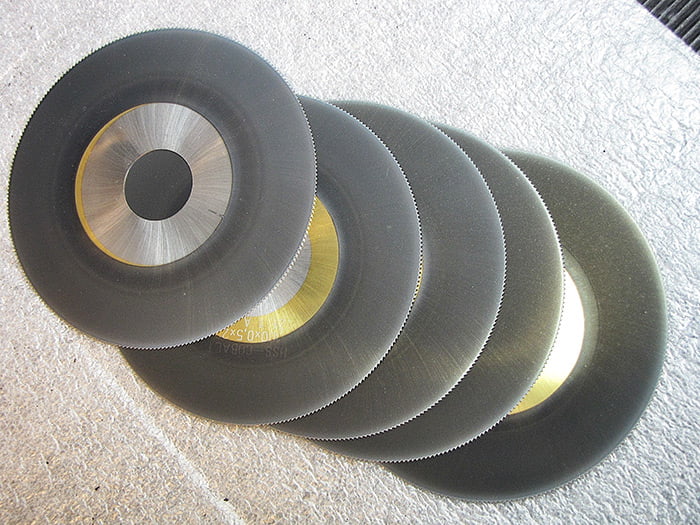

UltraImpact thin coatings PVD – PHYSICAL VAPOUR DEPOSITION Fine coating process (2-5µm thick) vacuum deposition where a material is transformed into steam, finally transported and deposited on the surface of a substrate. ADVANTAGES Increased performance life (Cutting tools, molds, dies, cutting and shaping, etc..) Reduced machine downtime Reduced maintenance costs […]

Read More

MoldLub Thin Coatings PVD – PHYSICAL VAPOUR DEPOSITION Fine coating process (2-5µm thick) vacuum deposition where a material is transformed into steam, finally transported and deposited on the surface of a substrate. ADVANTAGES Increased performance life (Cutting tools, molds, dies, cutting and shaping, etc..) Reduced machine downtime Reduced maintenance costs […]

Read More

Galaxy thin coatings PVD – PHYSICAL VAPOUR DEPOSITION Fine coating process (2-5µm thick) vacuum deposition where a material is transformed into steam, finally transported and deposited on the surface of a substrate. ADVANTAGES Increased performance life ( Cutting tools , molds, dies, cutting and shaping , etc. . ) Reduced […]

Read More

DiaPlus thin coatings PVD – PHYSICAL VAPOUR DEPOSITION Fine coating process (2- 5µm thick) vacuum deposition where a material is transformed into steam , finally transported and deposited on the surface of a substrate. ADVANTAGES Increased performance life ( Cutting tools , molds, dies, cutting and shaping , etc. . […]

Read More

DiExtra thin coatings PVD – PHYSICAL VAPOUR DEPOSITION Fine coating process (2- 5µm thick) vacuum deposition where a material is transformed into steam , finally transported and deposited on the surface of a substrate. ADVANTAGES: Increased performance life ( Cutting tools , molds, dies, cutting and shaping , etc. . […]

Read More

HardTiC thin coatings PVD – PHYSICAL VAPOUR DEPOSITION Fine coating process (2- 5µm thick) vacuum deposition where a material is transformed into steam , finally transported and deposited on the surface of a substrate. ADVANTAGES Increased performance life ( Cutting tools , molds, dies, cutting and shaping , etc. . […]

Read More

HardSilk thin coatings PVD – PHYSICAL VAPOUR DEPOSITION Fine coating process (2-5µm thick) vacuum deposition where a material is transformed into steam, finally transported and deposited on the surface of a substrate. ADVANTAGES Increased performance life (Cutting tools, molds, dies, cutting and shaping, etc..) Reduced machine downtime Reduced maintenance costs […]

Read More

HardTiN thin coatings PVD – PHYSICAL VAPOUR DEPOSITION Fine coating process (2-5µm thick) vacuum deposition where a material is transformed into steam, finally transported and deposited on the surface of a substrate. ADVANTAGES Increased performance life (Cutting tools, molds, dies, cutting and shaping, etc..) Reduced machine downtime Reduced maintenance costs […]

Read More

HardTiL Thin Coatings PVD – PHYSICAL VAPOUR DEPOSITION Fine coating process (2- 5µm thick) vacuum deposition where a material is transformed into steam , and finally transported deposited on the surface of a substrate. VANTAGENS Increased performance life ( Cutting tools , molds, dies, cutting and shaping , etc. . […]

Read More

HardCrom thin coatings PVD – PHYSICAL VAPOUR DEPOSITION Fine coating process (2-5µm thick) vacuum deposition where a material is transformed into steam, finally transported and deposited on the surface of a substrate. ADVANTAGES Increased performance life (Cutting tools, molds, dies, cutting and shaping, etc..) Reduced machine downtime Reduced maintenance costs […]

Read More