TECHNOLOGIES

LASER

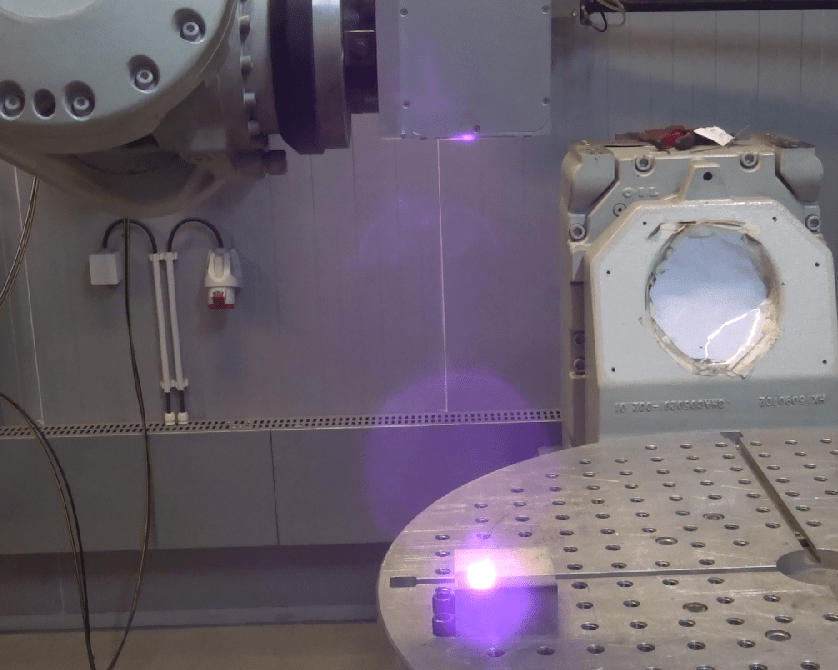

LASER HARDENING

THICK COATINGS

Hardening steels and ferrous materials transforms their microstructure by raising the surface temperature in a controlled manner, followed by rapid cooling.

The hardening process using sophisticated high-power lasers, combined with state-of-the-art control software, is the best process for surface hardening of components, even the most delicate ones with complex geometry. Thanks to the high control of the thermal input (temperature, energy density, etc.) confined only to the areas to be hardened, it is possible to treat parts and/or surfaces that would be impossible to harden with conventional technologies and processes, including induction. In addition, the precise control of the process makes it possible to efficiently regulate the heating and cooling of the zones to be hardened, achieving higher hardnesses than in conventional processes.